Optimal Timing for Wrought Iron Gate Repairs

Spring offers ideal conditions for repairs due to mild weather and low humidity.

Summer provides longer daylight hours, but high temperatures can affect paint and coatings.

Fall's cooler temperatures and low rainfall make it suitable for durable repairs before winter.

Ways to make Wrought Iron Gate Repairs work in tight or awkward layouts.

Popular materials for Wrought Iron Gate Repairs and why they hold up over time.

Simple add-ons that improve Wrought Iron Gate Repairs without blowing the budget.

High-end options that actually feel worth it for Wrought Iron Gate Repairs.

Finishes and colors that play nicely with Wrought Iron Gate Repairs.

Wrought iron gate repairs are essential for maintaining security, functionality, and aesthetic appeal. Proper timing ensures that repairs are effective and long-lasting. Weather conditions, temperature, and humidity significantly impact the quality of repair work, especially when it involves painting, welding, or coating. Repairing during favorable seasons minimizes issues such as rusting, peeling paint, or warping, which can be exacerbated by extreme weather.

Extreme cold or heat can hinder the adhesion of paint and coatings, affecting durability.

Scheduling repairs in moderate weather reduces the risk of rework and prolongs gate lifespan.

Timely repairs before winter or summer can prevent extensive damage and costly fixes.

Low humidity and temperatures between 50-85°F are ideal for painting wrought iron gates.

Spring's mild climate allows for thorough cleaning and repainting.

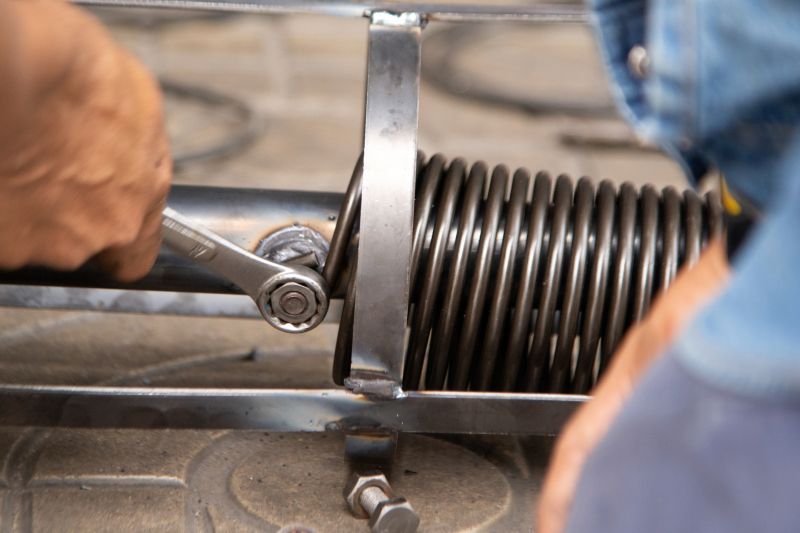

Summer is suitable for welding and structural repairs during dry, warm days.

Fall is optimal for applying protective coatings before winter.

Winter repairs are possible but require careful planning due to cold and moisture.

Little measurements that prevent headaches on Wrought Iron Gate Repairs day.

A 60-second routine that keeps Wrought Iron Gate Repairs looking new.

| Season | Ideal Repair Activities |

|---|---|

| Spring | Cleaning, repainting, rust removal |

| Summer | Structural repairs, welding, coating |

| Fall | Protective coating application, minor repairs |

| Winter | Limited repairs, maintenance checks |

Choosing the right time for wrought iron gate repairs can extend the life of the gate and improve its appearance. Properly scheduled repairs during suitable weather conditions ensure that coatings adhere well and that rust removal is effective. Regular maintenance, aligned with seasonal weather patterns, can prevent costly repairs and preserve the structural integrity of wrought iron gates.

Restoration involves cleaning, rust removal, and repainting for longevity.

Applying protective coatings during optimal weather prevents rust formation.

Structural issues are best addressed during warm, dry conditions.

Proper surface preparation and weather conditions are critical for lasting paint jobs.

A frequent mistake in Wrought Iron Gate Repairs and how to dodge it.

Small tweaks to make Wrought Iron Gate Repairs safer and easier to use.

Lower-waste or water-saving choices for Wrought Iron Gate Repairs.

The short, realistic tool list for quality Wrought Iron Gate Repairs.

Timely repairs and maintenance play a vital role in preserving wrought iron gates. Scheduling work during appropriate seasons minimizes weather-related complications and enhances the durability of repairs. Regular inspections and preventive measures can help identify issues early, reducing the need for extensive future repairs.

Interested in scheduling wrought iron gate repairs? Filling out the contact form can connect with professionals experienced in optimizing repair timing and techniques to ensure lasting results.